High-speed, accurate, and stable 3D printing for

perfect jewelry designs.

Powered by a 16K monochrome LCD screen, ENKA delivers ultra-fine surface quality for high-precision jewelry production. Its large 224 × 127 × 240 mm build volume supports everything from small rings to long and detailed chain models.

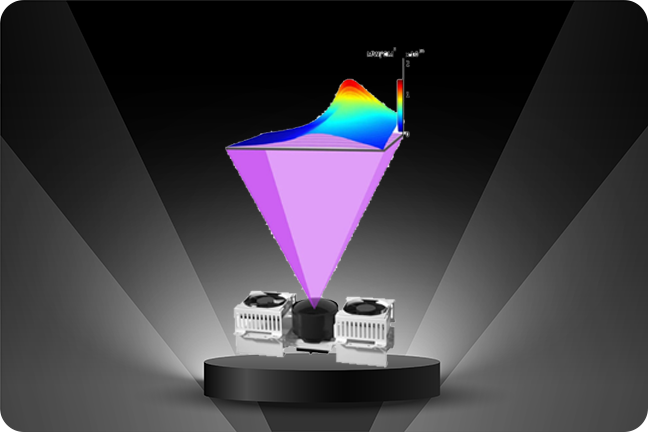

ENKA PRO is built for industrial jewelry production, combining 16K LCD technology with its projector-enhanced system to deliver DLP-level print quality. With a massive 302 × 161 × 380 mm build volume, you can print large batches of rings, chains, and complex models — all with smooth surfaces and sharp detail in just a minimum of 2 seconds per layer.

Equipped with a high-precision Japanese EPSON printhead and a 405 nm UV light system, it delivers sharp, full-color prints on flat metal surfaces like gold, silver, copper, and more. With an A4-size print area (297 × 210 mm), it’s ideal for cuban chains, pendants, bracelet blanks, and coins.

RIO is a yellow-colored, wax-based castable resin with 20% wax content — ideal for filigree and ultra-fine jewelry structures. It delivers sharp edges and clean surfaces, making it perfect for high-detail models.

BALI is a green-colored castable resin containing 30% wax — perfect for bangles, rings, and gem-set models that require flawless surface quality. It minimizes polishing after casting and ensures smooth, consistent results.

The Bulunmaz Mega Washing Station is a high-capacity, all-in-one post-processing unit designed for jewelry 3D printing. It combines washing, drying, and UV curing in a single machine — saving time, space, and labor.

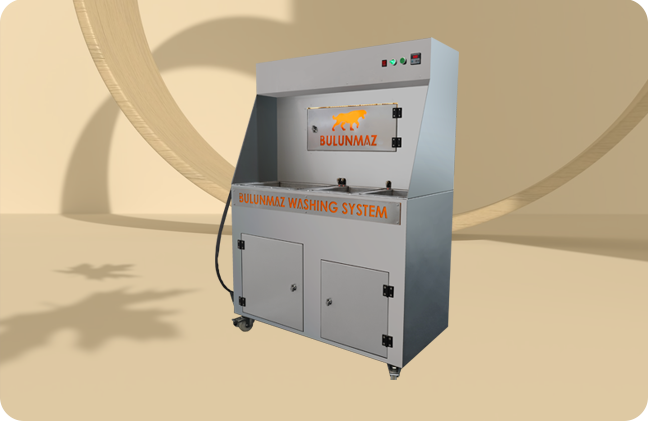

The Bulunmaz Washing Station is a compact desktop cleaning unit designed for post-processing jewelry 3D models. With its dual-tank setup and 10-liter capacity per tank, it enables a step-by-step cleaning process using isopropyl alcohol.

The Bulunmaz Curing Machine is a dedicated UV curing unit designed to finalize 3D printed jewelry models with maximum accuracy. Featuring a 4-inch touchscreen control panel, it allows users to adjust curing time based on resin type and model complexity.